Wednesday, December 2, 2020 – Kitchen Cabinets

- Mary Reed

- Dec 8, 2020

- 8 min read

I walk in an industrial area by a manufacturer of kitchen cabinets for apartments, condominiums and townhouses. Kitchen cabinets are one of those necessary things that not everybody pays a lot of attention to. I think they vary by country. When I was in San Miguel de Allende, Mexico for a month, most of the typical houses did not have upper kitchen cabinets — only lower ones. In some U.S. houses the cabinets go all the way to the ceiling. My parents’ house had cabinets like those. You had to stand on a stepladder to reach the highest one. Remodeling a kitchen with new cabinets is a major undertaking. My sister Barbara and her husband Phil recently expanded their kitchen including LOTS of new cabinets. It was quite an extensive process taking months to complete, but the end result was spectacular. The kitchen is the heart of the home after all, and it should be an inviting, efficient place to gather. If you want to find out more about kitchen cabinets, read on.

History

According to Wikipedia, as commonly used today, the term “kitchen cabinet” denotes a built-in kitchen installation of either a floor or a wall cabinet. Typically, multiple floor cabinets are covered by a single counter and floors and walls are not accessible behind and under the cabinets. Kitchen cabinets per se were invented in the 20th century. A precursor — not built-in — was the Hoosier cabinet of the 1910s, a single piece of furniture incorporating storage and work surfaces, of which over 2 million were sold by 1920.

Pre-WW-I cabinet design. Typical kitchens before World War I used freestanding work tables and a pantry for dry storage. Cupboards were sometimes used in kitchens, though in larger houses dishes were more typically stored in the dining room or butler's pantry. Perishable foods such as milk, meat and vegetables were purchased daily.

Post-WW-I industrial era. Increasing interest in household efficiency led to pioneering motion studies of housework in the 1920s by industrial psychologist Lillian Moller Gilbreth. Subsequent improvements in kitchen design set the stage for the familiar built-in cabinetry of the present day. At the time, work surfaces were typically made of linoleum or stainless steel. Improvements in technology eventually made industrial-scale cabinet production possible.

Post-WW-II cabinet design. In the U.S., countertops of high-pressure laminates such as Formica became popular. Laminates led to the adoption of the seamless flush-surface kitchen design that is common today, though laminates themselves began to be supplanted by solid surface materials, such as stone and quartz. In Europe, built-in cabinets had also been pioneered in the 1920s. With improved materials, the frameless cabinet style, notable for its architectural minimalism reminiscent of Bauhaus design, emerged in European kitchen design and was soon adopted worldwide.

Post-modern cabinet design trends. Other elements of kitchen design affect the choice of cabinetry. For example, post-modern kitchens tend to be characterized by hardwood floors, earth tones, and bare walls in place of wallpaper which, in turn, affect cabinetry choices. Various trends include the introduction of more expensive options, space-saving measures, a larger number of ovens, thicker countertops of 2–3 inches, taller base cabinets, honed finishes, taller countertop appliances, undercounter and task lighting, and higher nine-foot ceilings. While these are general kitchen design trends, they have also influenced cabinetry.

Kitchens today. Modern kitchen design has improved partly as a result of ergonomic research. Functionality is important; one research study had "anthropological scientists" observing homeowners "interact" with their kitchen cabinets. Kitchens are larger and have more cabinets; some kitchens may have as many as 50 drawers and cabinet doors. New features today include deep drawers for cookware, pull-out shelves to avoid excess bending, sponge trays on the front of sink cabinets, pullout hideaway garbage/recycling containers, pull-out spice cabinets, lazy susans in corner cabinets, vertical storage for cookie sheets, full-extension drawer slides and drawers and doors with so-called soft-close/positive-close mechanisms enabling drawers to shut quietly or which shut fully after being pushed only partially. As housing stocks get older, many homeowners face problems with visually unappealing older kitchen cabinets; in such situations, there is a choice to buy new (most expensive), reface existing (less expensive) or to strip and refinish existing (least expensive if done by the homeowner) cabinets.

By 2009, there was more emphasis on cabinets designed with environmental factors in mind. So-called "green cabinets" were becoming more popular. As homes in Western countries became more airtight to save on heating and cooling costs, air quality has sometimes suffered as gases which are released from resins as they cure. Resins — organic materials which convert from liquid to solid form — are used to manufacture engineered wood e.g., particleboard which is used frequently to build kitchen cabinet carcases and can be a factor. According to a recent report:

Considering that North Americans spend a large proportion of their lives indoors, it’s clear why this is a key issue in designing healthy spaces. Additionally, air quality is not a stand-alone problem; rather, every other component of the home can affect air quality. Air quality can be compromised by off-gassing from cabinetry, countertops, flooring, wall coverings or fabrics; by cooking by-products released into the air and by mold caused by excess moisture or poor ventilation.

Universal design. Some designers have begun to build houses and cabinetry to address the needs of users throughout the human life cycle and among all user capabilities, under a concept called universal design. The United States requires universal design for federally funded housing, under the Americans with Disabilities Act of 1990. Universal design features include easily manipulated handles, low switches and numerous other innovations.

Face-frame cabinets. Traditional cabinets are constructed using face frames which typically consist of narrow strips of hardwood framing the cabinet box opening. Cabinet carcasses were traditionally constructed with a separate face frame until the introduction of modern engineered wood such as particle board and medium-density fiberboard, along with glues, hinges and fasteners required to join them. A face frame ensures squareness of the cabinet front. It also increases rigidity and provides a mounting point for hinges. Face-frame cabinets retain popularity in the U.S. An important distinction between modern manufactured and traditional custom-built face-frame cabinets relates to the catalog-selection of cabinet components entailed by mass production. Original custom face-frame cabinets accommodated multiple sections or cavities in a single carcass. But stock or semi-custom face-frame cabinets are constructed individually and joined during installation. As a result, modern face-frame cabinets differ in having significantly wider — double-width — stile materials overall after installation. Two 1 1⁄2-inch stiles joined as adjacent cabinets result in, effectively, a 3-inch stile. Wide stiles can interfere with access to the cabinet interior. When base cabinets were typically shelved, this was not much of a drawback. But with base cabinets increasingly being fitted with trays and drawers using modern hardware, the extra stile width results in significantly less access to the cabinet cavity space. This drawback does not pertain to custom face-frame cabinets.

Custom cabinets. Custom face-frame cabinets offer more efficient use of space because double width stiles can be avoided. They also provide far greater flexibility with regard to materials and design, since kitchen cabinet heights, widths and depths can be designed and produced according to the client's specifications. Every aspect of custom cabinetry can be made to specifications, which makes it both the most desirable and the most expensive choice in the majority of kitchen installations.

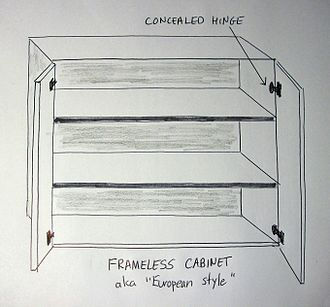

Frameless full-access cabinets. Frameless — aka "full-access" — cabinets utilize the carcass side, top, and bottom panels to serve the same functions as do face-frames in traditional cabinets. In general, frameless cabinets provide better utilization of space than face-frame cabinets. A preference for frameless cabinet design developed in Europe in the 1950s and 1960s following the devastation of World War II and the increasing cost of lumber. A burgeoning market for reconstructed housing in Central Europe offered a fertile environment for developments in efficient hinge and cabinet designs. Frameless cabinets rely on manufacturing methods that permit the production of modern cabinet hardware — hinges and slides — and engineered wood products for strength, dimensional tolerance and stability. The intent of the frameless design is to achieve a more streamlined appearance and a more efficient use of space, with ergonomically designed moving components such as drawers, trays and pull-out cabinets providing better access to interior components. Many benefits stemming from frameless cabinet design have been successfully applied to face-frame cabinets, such as multiple drawers in base cabinets, full-overlay doors and cup hinges. With the rise in popularity of European-style frameless cabinetry, a significant proportion of the hardware used by U.S. cabinet manufacturers is imported from Europe.

Frames. In the U.S., solid wood frame and panel construction, using either mortise and tenon or cope and stick jointed frames, is traditional with maple, cherry, oak, birch and hickory among the most commonly used species. Mortise-and-tenon frames — with their greater strength and permanence — are more costly to produce and less commonly used as compared to cope-and-stick frames. As an alternative, miter joint frames — which may be identifiable by face-surface relief that follows continuously around the frame — have become popular. Miter-jointed frames typically employ embedded metal fasteners to secure frames elements (stiles and rails) cut at a 45° angle. Captured within frames, panels may be either solid or veneered engineered wood, either particle board or medium density fiberboard. Laminates, including those designed to resemble hardwood, can typically be identified by a more rounded appearance associated with the minimum bending radii necessarily entailed by the manufacturing process of applying laminate to an underlying substrate. By comparison, solid surfaces — and solid hardwoods in particular — can be milled with more sharply defined corners, edges or grooves on either a panel or frame.

Panels. Panels used in frame-and-panel kitchen cabinet doors may be fashioned either of solid wood or covered by paint, veneer or laminate in which case they are fashioned of engineered wood. The panels are typically not fastened with glue or nails but rather "float" within the frame to accommodate seasonal expansion or contraction of the wood frame.

Solid-door construction. Doors may be fabricated of solid material, either engineered wood — particle board or medium-density fiberboard, but not typically plywood — or solid wood. Engineered wood panels may either be used as slabs or may be shaped to resemble frame-and-panel construction. In either case, engineered wood panels are generally painted, veneered or laminated. Solid wood panels are typically formed of multiple boards of the selected wood species, jointed together using glue and may either be painted or finished. Solid wood construction offers the possibility of refinishing in case of damage or wear.

Decorative panels. Cabinet doors panels can be used decoratively on cabinet sides, where exposed, for a more finished appearance.

Glass door construction options. Doors may have glass windows constructed of muntins and mullions holding glass panels as in exterior windows. Other designs either mimic the divided-light look of muntins and mullions with overlays or may dispense with them altogether. Cabinets using glass doors sometimes use glass shelves and interior lighting from the top of a cabinet. A glass shelf allows light to reach throughout a cabinet. For a special display effect, the interior rear of a cabinet may be covered with a mirror to further distribute light.

Cabinet hardware. Hardware is the term used for metal fittings incorporated into a cabinet extraneous of the wood or engineered wood substitute and the countertop. The most basic hardware consists of hinges and drawer/door pulls, although only hinges are an absolute necessity for a cabinet since pulls can be fashioned of wood or plastic, and drawer slides were traditionally fashioned of wood. In a modern kitchen it is highly unusual to use wood for drawer slides owing to the much superior quality of metal drawer slides/sides.

Comments