Tuesday, September 21, 2021 – Scissors

- Mary Reed

- Sep 22, 2021

- 17 min read

In the photo are a couple of pairs of scissors that I have. Scissors are that essential tool that we take for granted. They have myriad uses for children and adults. Young children often use those blunt-end scissors for craft projects involving colored construction paper, paper plates, notebook paper, paper cups, etc. Adults, on the other hand, have many different styles of scissors depending on the task they are designed to do. Barbers and beauty shop stylists have different kinds of cutting shears. Landscapers have grass shears, hedge trimmers, loppers, pruning shears, etc. Chefs and home cooks have kitchen scissors and poultry shears. Manicurists have nail scissors. Machinists have different kinds of snips and hydraulic cutters. Health professionals have trauma shears, dissection scissors, surgical scissors, iris scissors, bandage scissors, etc. Seamstresses and tailors have dressmaker’s shears, pinking shears, buttonhole scissors, embroidery snips, etc. I have used scissors for craft projects, hair-cutting and sewing. I knew a seamstress who never used pins to attach her patterns to fabric. Instead, she just put heavy objects on the patterns — including plates or saucers for the curved portions — and cut around them. It could be argued that scissors are one of the basic necessities of life. Let’s learn more about them.

According to Wikipedia, scissors are hand-operated shearing tools. A pair of scissors consists of a pair of metal blades pivoted so that the sharpened edges slide against each other when the handles opposite to the pivot are closed. Scissors are used for cutting various thin materials, such as paper, cardboard, metal foil, cloth, rope and wire. A large variety of scissors and shears all exist for specialized purposes. Hair-cutting shears and kitchen shears are functionally equivalent to scissors, but the larger implements tend to be called shears. Hair-cutting shears have specific blade angles ideal for cutting hair. Using the incorrect type of scissors to cut hair will result in increased damage, split ends or both, by breaking the hair. Kitchen shears — also known as kitchen scissors — are intended for cutting and trimming foods such as meats.

Modern scissors are often designed ergonomically with composite thermoplastic and rubber handles which enable the user to exert either a power grip or a precision grip.

Terminology

The noun “scissors” is treated as a plural noun, and therefore takes a plural verb e.g., these scissors are. Alternatively, the tool is referred to by the singular phrase “a pair of scissors.” The word “shears” is used to describe similar instruments that are larger in size and for heavier cutting.

History

The earliest known scissors appeared in Mesopotamia 3,000 to 4,000 years ago. These were of the “spring scissor” type comprising two bronze blades connected at the handles by a thin, flexible strip of curved bronze which served to hold the blades in alignment — to allow them to be squeezed together and to pull them apart when released.

Spring scissors continued to be used in Europe until the 16th century. However, pivoted scissors of bronze or iron, in which the blades were pivoted at a point between the tips and the handles — the direct ancestor of modern scissors — were invented by the Romans around 100 AD. They entered common use in not only ancient Rome, but also China, Japan and Korea; the idea is still used in almost all modern scissors.

The Roman shears in the photo have a style of "Egyptianizing" metal inlay designs, suggesting they were made to imitate actual Egyptian art. When closed, the dog and cat figures at the tips come face to face.

Early manufacture

During the Middle Ages and Renaissance, spring scissors were made by heating a bar of iron or steel, then flattening and shaping its ends into blades on an anvil. The center of the bar was heated, bent to form the spring, then cooled and reheated to make it flexible.

The Hangzhou Zhang Xiaoquan Co. in Hangzhou, China, has been manufacturing scissors since 1663.

William Whiteley & Sons (Sheffield) Ltd. was producing scissors by 1760, although it is believed the business began trading even earlier. The first trademark, 332, was granted in 1791. The company is still manufacturing scissors today, and is the oldest company in the West to do so.

Pivoted scissors were not manufactured in large numbers until 1761, when Robert Hinchliffe of Sheffield produced the first pair of modern-day scissors made of hardened and polished cast steel. His major challenge was to form the bows; first, he made them solid, then drilled a hole, and then filed away metal to make this large enough to admit the user's fingers. This process was laborious, and apparently, he improved upon it to increase production. He lived in Cheney Square — now the site of Sheffield Town Hall — and set up a sign identifying himself as a "fine scissor manufacturer." He achieved strong sales in London and elsewhere.

During the 19th century, scissors were hand-forged with elaborately decorated handles. They were made by hammering steel on indented surfaces known as “bosses” to form the blades. The rings in the handles — known as bows — were made by punching a hole in the steel and enlarging it with the pointed end of an anvil.

In 1649, in Swedish-ruled Finland, an ironworks was founded in the village of Fiskars between Helsinki and Turku. In 1830, a new owner started the first cutlery works in Finland, making — among other items — scissors with the Fiskars trademark.

Scissor anatomy

According to Emberleaf Workshops at emberleaf.com:

1. Finger ring – the place where you put

your finger. Scissors have a “finger

ring” and a “thumb ring.”

2. Shaft – attaches the finger rings to

the pivot. Sometimes these can be

smooth or molded.

3. Pivot screw – holds the two scissors

together.

4. Inner blade – the side of the blades

that face each other. Most scissors

have hollow ground inner blades.

5. Blade – the sharp part of the shears. Edges are either convex (Japanese style) or

beveled (German style).

6. Ride line – the smooth, shiny line along the edge of the inner blade.

7. Point or tip – where both blades meet when the scissors are closed against its stopper.

8. Spine – the thickest part of the blade, usually opposite the cutting edge but may be

down the center of the blade in sword-edge shears.

9. Outer blade – the side of the blade that shapes the scissors’ edge.

10. Insert rings – a plastic or rubber ring that fits inside the finger and thumb rings to make

the holes smaller to custom-fit a hand.

11. Stopper – a rubber or plastic insert that allows the scissors to close at the tip in the

correct position.

12. Half-moon – a smooth area behind the pivot where the blades move over each other.

13. Logo – indicates what company made the scissors and often includes model

identification, size and steel used.

14. Finger rest or tang – place where the pinky finger rests. Tangs are either fixed or

removable, if present at all.

Operation

According to Wikipedia, mechanically, scissors are a first-class double-lever with the pivot acting as the fulcrum. For cutting thick or heavy material, the mechanical advantage of a lever can be exploited by placing the material to be cut as close to the fulcrum as possible. For example, if the applied force at the handles is twice as far away from the fulcrum as the cutting location i.e., the point of contact between the blades, the force at the cutting location is twice that of the applied force at the handles. Scissors cut material by applying at the cutting location a local shear stress which exceeds the material's shear strength.

Some scissors have an appendage called a finger brace or finger tang below the index finger hole for the middle finger to rest on — to provide for better control and more power in precision cutting. A finger tang can be found on many quality scissors (including inexpensive ones) and especially on scissors for cutting hair. In hair-cutting, some claim the ring finger is inserted where some place their index finger, and the little finger rests on the finger tang.

For people who do not have the use of their hands, there are specially designed foot-operated scissors. Some quadriplegics can use a motorized mouth-operated style of scissors.

Left-handed and right-handed scissors

Most scissors are best suited for use with the right hand, but left-handed scissors are designed for use with the left hand. Because scissors have overlapping blades, they are not symmetric. This asymmetry is true regardless of the orientation and shape of the handles: the blade that is on top always forms the same diagonal regardless of orientation. Human hands are also asymmetric, and when closing, the thumb and fingers do not close vertically, but have a lateral component to the motion. Specifically, the thumb pushes out from the palm and the fingers pull inwards. For right-handed scissors held in the right hand, the thumb blade is closer to the user's body, so that the natural tendency of the right hand is to force the cutting blades together. Conversely, if right-handed scissors are held in the left hand, the natural tendency of the left hand would be to force the cutting blades laterally apart. Furthermore, with right-handed scissors held by the right hand, the shearing edge is visible, but when they are used with the left hand, the cutting edge of the scissors is behind the top blade, and one cannot see what is being cut.

Some scissors are marketed as ambidextrous. These have symmetric handles so there is no distinction between the thumb and finger handles and have very strong pivots so that the blades simply rotate and do not have any lateral give. However, most "ambidextrous" scissors are in fact still right-handed in that the upper blade is on the right, and hence is on the outside when held in the right hand. Even if they cut successfully, the blade orientation will block the view of the cutting line for a left-handed person. True ambidextrous scissors are possible if the blades are double-edged, and one handle is swung all the way around to almost 360 degrees, so that the back of the blades become the new cutting edges. U.S. Patent 3,978,584 has been awarded for true ambidextrous scissors.

Gardening, agriculture and animal scissors

Hedge trimmers

A hedge trimmer, shrub trimmer or bush trimmer is a gardening tool or machine used for trimming — cutting or pruning — hedges or solitary shrubs or bushes. Different designs as well as manual and powered versions of hedge trimmers exist.

Grass shears

Grass shears differ from pruning shears in being long-handled and having the handles at right angles to the blades. Two kinds are available: with the blades horizontal and with the blades vertical. Horizontal blades are used to remove grass which has not been cut by the lawn mower, while vertical blades are used for trimming the edges of a lawn.

In 1939, a version of the vertical grass shears was invented having a long handle with a lever at the top, and wheels at the bottom with the shears. This enabled the user to trim the edge of the grass near the sidewalk and driveway. For all practical purposes, powered trimmers have replaced this type of grass shears.

Pruning shears

Pruning shears — also called hand pruners (in American English) or secateurs (in British English) — are a type of scissors for use on plants. They are strong enough to prune hard branches of trees and shrubs, sometimes up to two centimeters thick. They are used in gardening, arboriculture, plant nursery works, farming, flower arranging and nature conservation, where fine-scale habitat management is required.

Loppers

Loppers are a type of scissors used for pruning twigs and small branches, like pruning shears with very long handles. They are the largest type of manual garden cutting tool.

They are usually operated with two hands, and with handles typically between 12 and 36 inches long to give good leverage. Some have telescopic handles which can be extended to a length of 6 1/2 feet, to increase leverage and to reach high branches on a tree. Loppers are mainly used for the pruning of tree branches with diameters less than 2 inches. Some of the newer lopper designs have a gear or compound lever system which increases the force applied to the blades or a ratchet drive.

Blade shears

Blade shears consist of two blades arranged similarly to scissors except that the hinge is at the end farthest from the point — not in the middle. The cutting edges pass each other as the shearer squeezes them together and shear the wool close to the animal's skin. Blade shears are still used today but in a more limited way. Blade shears leave some wool on a sheep, and this is more suitable for cold climates such as the Canterbury high country in the South Island of New Zealand where approximately half a million sheep are still shorn with blade shears each year. For those areas where no powered machinery is available, blade shears are the only option. In Australia blades are more commonly used to shear stud rams.

Food and drug scissors

Kitchen scissors or shears

Kitchen scissors or shears are used for food preparation, but often used for a variety of other purposes. Today, kitchen scissors are usually made from stainless steel for food hygiene and oxidization-resistance reasons. They often have kitchen functionality — other than cutting — incorporated, such as bottle-cap, to fish scale, to crack nuts and bottle-openers built into the handles.

Poultry shears

Poultry shears used to cut, break or trim tougher textured food items. The skin or bones of poultry are typical examples of hard-to-cut parts of food being prepared. The shears most often are made of stainless steel with heavy duty curved blades that allow a firmer grip and more powerful pressure applied to cutting. A notched and serrated blade is also common to allow for better gripping, holding and cutting through bones or tough materials.

Cigar cutter

A cigar cutter is a mechanical device designed to cut one end off a cigar, so that it may be properly smoked. Although some cigars are cut on both ends, or twirled at both ends, the vast majority come with one straight cut end and one end in a "cap" which must be cut off for the cigar to be smoked. Most quality handmade cigars — regardless of shape — will have a cap which is one or more small pieces of a wrapper pasted onto one end of the cigar with either a natural tobacco paste or with a mixture of flour and water. The cap end of a cigar is the rounded end without the tobacco exposed, and this is the end one should always cut. The cap may be cut with a knife or bitten off, but if the cap is cut jaggedly or without care, the end of the cigar will not burn evenly and smokeable tobacco will be lost.

Grooming

Haircutting shears

Haircutting shears are scissors that are specifically designed for cutting hair. They are also known as barber shears, hairdressing shears or hair shears. They range in size from about 5 to 7 inches long and commonly have an appendage, known as a finger brace or tang, attached to one of the finger rings. This gives the user additional control when cutting. A swiveling thumb ring is new technology in shear design. The swivel shear offers increased flexibility and the ability to keep the wrist straight and the elbow down in all cutting positions, creating more comfort and control.

Texturizing shears

A specialized type of haircutting shears known as texturizing shears are used to reduce hair thickness, to create texturizing effects or to blend layered hair. Texturizing shears have a pair of pivoted blades in the same way as normal shears, but one or both blades have teeth on the edge like a comb. These teeth allow for only some of the hair in a section to be cut in an even fashion, while other parts of that section are left alone. There are also texturizing shears that can come in a range of numbers in teeth, varying how much hair can be thinned out. Texturizing shears may also be called thinning shears or chunking shears.

Nail scissors

Nail scissors are small scissors with a slender shaft and brief curved blades that are used chiefly for shaping and trimming the fingernails and toenails.

Mustache and beard scissors

Mustache and beard scissors are 5-inch scissors made from top-quality Japanese steel and are extremely sharp and precise, perfect for hefty cuts or delicate cuts. They also come with a removable finger rest, adjustable tension knob to make the scissors cut faster or slower and rubber comfort ring inserts because your fingers will get sore during extended use without them.

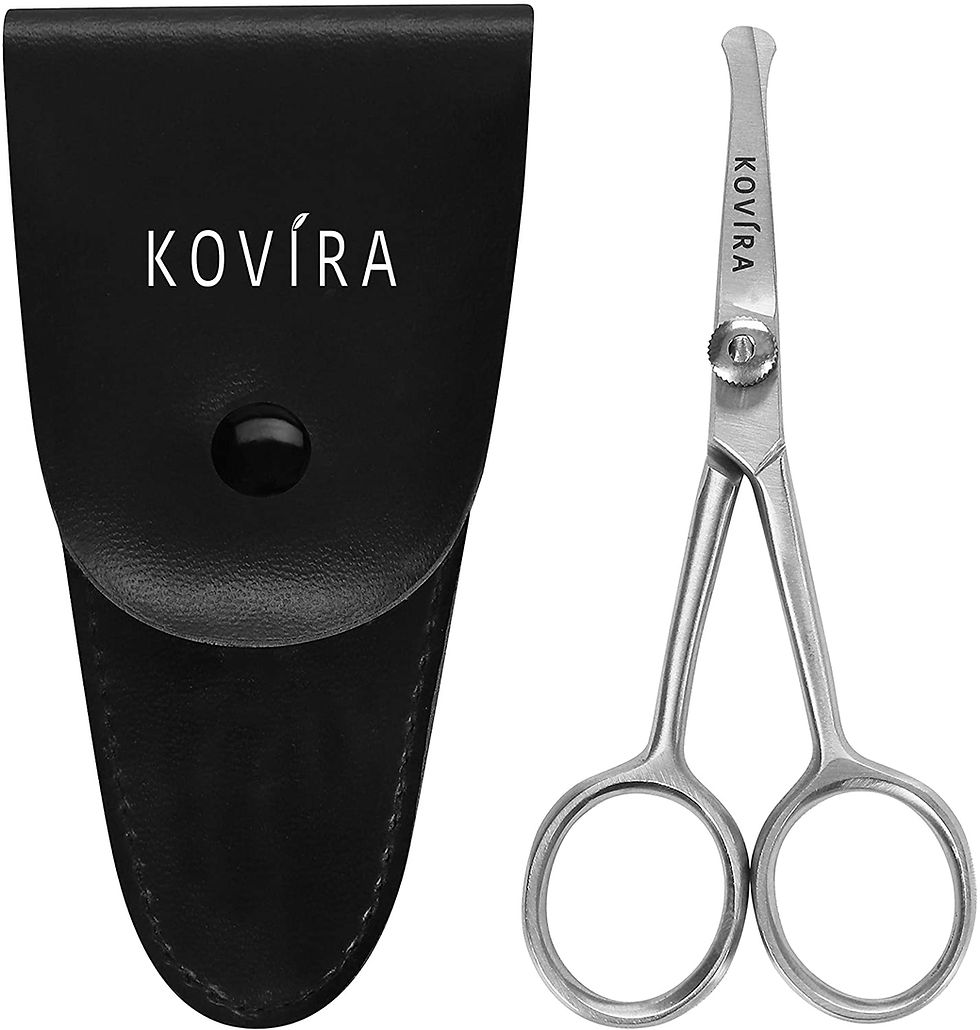

Nose hair scissors

Nose scissors feature razor-sharp, 4-inch blades that isolate each nasal hair for accuracy, precision and control. They are made of Japanese stainless steel. The tips of the blade feature a rounded tip. It provides safety when cutting up the nose to trim those stray, coarse, unruly nose hairs. With the round tip at the end of the blades, it makes the scissors safe to be used to trim ear hair.

Metalwork

Tin snips

Tin snips are one of the most popular type of snips. They are defined by their long handles and short blades. They usually have extra wide jaws and are made of drop forged carbon steel. Depending on the size of the blade, tin snips can cut between 24 and 16 gauge cold rolled low-carbon tin. They can be ranged in length from 7 to 14 inches long. There are two main types: straight-pattern and duckbill-pattern. Straight-pattern are best for straight cuts but can handle gentle curves. Duckbill-pattern snips — also known as trojan-pattern snips — have blades that taper down from the pivot to the tip of the blades. The blade edges are also beveled to more easily cut curves and circles or shapes. They are a lighter duty snip that can only cut up to 25-gauge mild steel.

Other common blade patterns include the circle pattern or curved pattern and the hawk's-bill pattern. Circle pattern snips have a curved blade and are used to cut circles. Hawk's-bill snips are used to cut small radii on the inside and outside of a circle. The shape of the blades allow for sharp turns without buckling the sheet metal. A common use is cutting holes in pipes.

Compound-action snips

Compound-action snips — also known as aviation snips, maille snips or sheet snips — are the most popular type of snips as they are able to exert a higher force compared to other types of snips of the same size because of the design of their linkage. They were first developed to cut aluminum in the construction of aircraft, hence they are often referred to as aviation snips. They can handle aluminum up to 18-gauge, mild steel up to 24-gauge or stainless steel up to 26-gauge.

There are three cutting styles for compound-action snips: straight cutting, left cutting and right cutting. Straight cutting snips (generally have yellow soft grips) cut in a straight line and wide curves; left cutting snips (usually red) will cut straight and in a tight curve to the left; right cutting snips (usually green) will cut straight and in a tight curve to the right. These different cutting styles are necessary because metal is stiff and heavy and does not move out of the way readily when cutting around a curve. The respective styles move the material out of the way when cutting in the direction they are designed for. The blades are usually serrated to prevent material slippage.

There are also upright and long cut configurations. The upright snip has the blades rotated 90° from the handles. This configuration is more ergonomic and commonly used in tight spaces. The long cut snip has long blades that make it easier to make long straight cuts. These snips are commonly used on vinyl or aluminum siding.

Standard compound-action snips are designed for cutting steel or softer materials, although the occasional use on stainless steel is not detrimental. For cutting through tougher materials, such as inconel and titanium, special hard snips are available. They are similar in design to standard or offset aviation snips but have specially heat-treated blades. These snips will have a different color handle to differentiate them from the other standard types.

Hydraulic cutter

Hydraulic rescue tools are used by emergency rescue personnel to assist in the extrication of victims involved in vehicle accidents, as well as other rescues in small spaces. These tools include cutters, spreaders and rams. Such devices were first used in 1963 as a tool to free race car drivers from their vehicles after crashes.

Throatless shear

A throatless shear is a cutting tool used to make complex straight and curved cuts in sheet metal. The throatless shear takes its name from the fact that the metal can be freely moved around the cutting blade — it does not have a throat down which metal must be fed — allowing great flexibility in shapes that can be cut.

Medical

Trauma shears

Trauma shears — also known as Tuff Cuts (a brand name) — are a type of scissors used by paramedics and other emergency medical personnel to quickly and safely cut clothing from injured people. They usually consist of a plastic handle with a metal blade, which is traditionally bent at about 150 degrees, giving them an unusual appearance as compared to normal scissors, and also a longer "lever arm."

The shears were designed exclusively for external use and are not suitable for surgical or invasive procedures. Their rugged construction enables them to cut through strong materials such as car seat belts, leather, denim and even thin metal and other hard surfaces — including a U.S. penny. They are increasingly being used by fishermen, soldiers and scuba divers as safer alternatives to knives.

The wide, blunt tip on the shears is designed to slide across skin, minimizing the risk of injuring the patient while cutting clothing.

Bandage scissors are similar in design, though smaller, and are primarily used for sizing or removing dressings and bandages.

Surgical scissors

Surgical scissors are surgical instruments usually used for cutting. They include bandage scissors, dissecting scissors, iris scissors, operating scissors, stitch scissors, tenotomy scissors, Metzenbaum scissors, plastic surgery scissors and Mayo scissors. Surgical scissors are usually made of stainless steel. Some scissors have tungsten carbide reinforcements along their cutting edges. The hardness of this material allows the manufacturers to create sharper edges, which allows for easier and smoother cuts and keeps the scissors sharp longer.

Metzenbaum scissors

Metzenbaum scissors are surgical scissors designed for cutting delicate tissue and blunt dissection. The scissors come in variable lengths and have a relatively long shank-to-blade ratio. They are constructed of stainless steel and may have tungsten carbide cutting surface inserts. The blades can be curved or straight, and the tips are usually blunt. This is the most common type of scissors used in organ-related operations.

Iris scissors

Iris scissors are a type of scissors with short blades that were originally developed for ophthalmic surgery. They are alternatively referred to as iris forceps in the United Kingdom and Asia. Iris scissors are also available in the crafting market and are sometimes used for the production of fabric-related goods. Both closed and open shank versions are available.

Mayo scissors

Mayo scissors are a type of surgical scissors, often used in the cutting of fascia. They were developed by Mayo Clinic surgeons. Straight- and curved-blade varieties of Mayo scissors exist, each of which is particularly suited to specific surgical, including veterinary and podiatric surgery applications.

Straight-bladed Mayo scissors are designed for cutting body tissues near the surface of a wound. As straight-bladed Mayo scissors are also used for cutting sutures, they are also referred to as "suture scissors."

Curved-bladed Mayo scissors allow deeper penetration into the wound than the type with straight blades. The curved style of Mayo scissor is used to cut thick tissues such as those found in the uterus, muscles, breast and foot. Mayo scissors used for dissection are placed in tissue with the tips closed. The scissors are then opened so that the tips open and spread out the tissue during the dissection process.

Sewing and clothes-making

All-purpose or crafting scissors

All-purpose or crafting scissors have long blades and pointy tips, designed to cut long, straight, smooth cuts in a variety of materials, as well as to get into small areas with the tips. In sewing applications, they are primarily used for non-fabric cutting applications, such as cutting out paper patterns.

Applique scissors

Applique scissors have an offset handle and paddle-shaped blade that pushes away the bottom layer of fabric, for controlled cuts close to the stitching. It is designed to cut/trim close to the fabric while protecting it from damage and is used for applique work and rug-making.

Buttonhole scissors

Buttonhole scissors are used for opening buttonholes without stretching or damaging stitches. This pair of scissors features an adjustable screw so all buttonholes can be cut at an even length.

Dressmaker’s shears

Dressmaker's shears have a long blade — typically 7–10 inches — to facilitate cutting out fabric. Blades are tapered, with one pointed and one rounded tip; the blunt tip prevents fabric from snagging on seams and threads. Blades have a "knife edge"; the top blade is set at an acute angle which allows them to cut through fabric easier than scissors. More heavy-duty than general scissors, the bottom blade sits flush on the table, making it easier to cut accurately through fabric.

Embroidery scissors

Embroidery scissors are small scissors without loopholes for the fingers, which have a fine pointy tip, designed to get close to the fabric without damaging it. These snips feature a curved blade, to facilitate getting as close as possible to the base of a thread without damaging the garment.

Pinking shears

Pinking shears are scissors with saw-toothed instead of straight blades. They produce a zigzag pattern instead of a straight edge.

Before pinking scissors were invented, a pinking punch or pinking iron was used to punch out a decorative hem on a garment. The punch would be hammered by a mallet against a hard surface and the punch would cut through the fabric. In 1874, Eliza P. Welch patented an "improved" design for the pinking iron, which featured a pair of handles.

The pinking shears design that's most well-known was patented by Louise Austin in 1893. In 1934, Samuel Briskman patented a pinking shear design; Felix Wyner and Edward Schulz were listed as the inventors. In 1952, Benjamin Luscalzo was granted a patent for pinking shears that would keep the blades aligned to prevent wear.

Pinking shears are used for cutting woven cloth. Cloth edges that are unfinished will easily fray, the weave becoming undone and threads pulling out easily. The sawtooth pattern does not prevent the fraying but limits the length of the frayed thread and thus minimizes damage.

These scissors can also be used for decorative cuts and a number of patterns — arches, sawtooth of different aspect ratios or asymmetric teeth — are available. True dressmaker's pinking shears, however, should not be used for paper decoration because paper dulls the cutting edge.

Tailor’s scissors

Tailor’s scissors are designed to cut through heavy-duty materials like leather or multiple layers of fabric. Generally shorter in length — 5-inch blades are typical — with thicker blades that feature precision-ground knife-edges which cut all the way to the tip.

Comments